Mobile Home Remodeling Tacoma WA breathes new life into living spaces and increases comfort, style, and value. However, it’s important to consider the potential risks and rewards before deciding to undertake this type of project.

For example, window problems should be addressed immediately to prevent water damage or mold and mildew growth. Other projects that typically offer the highest return include kitchen and bathroom remodels, flooring replacement, and energy-efficient upgrades.

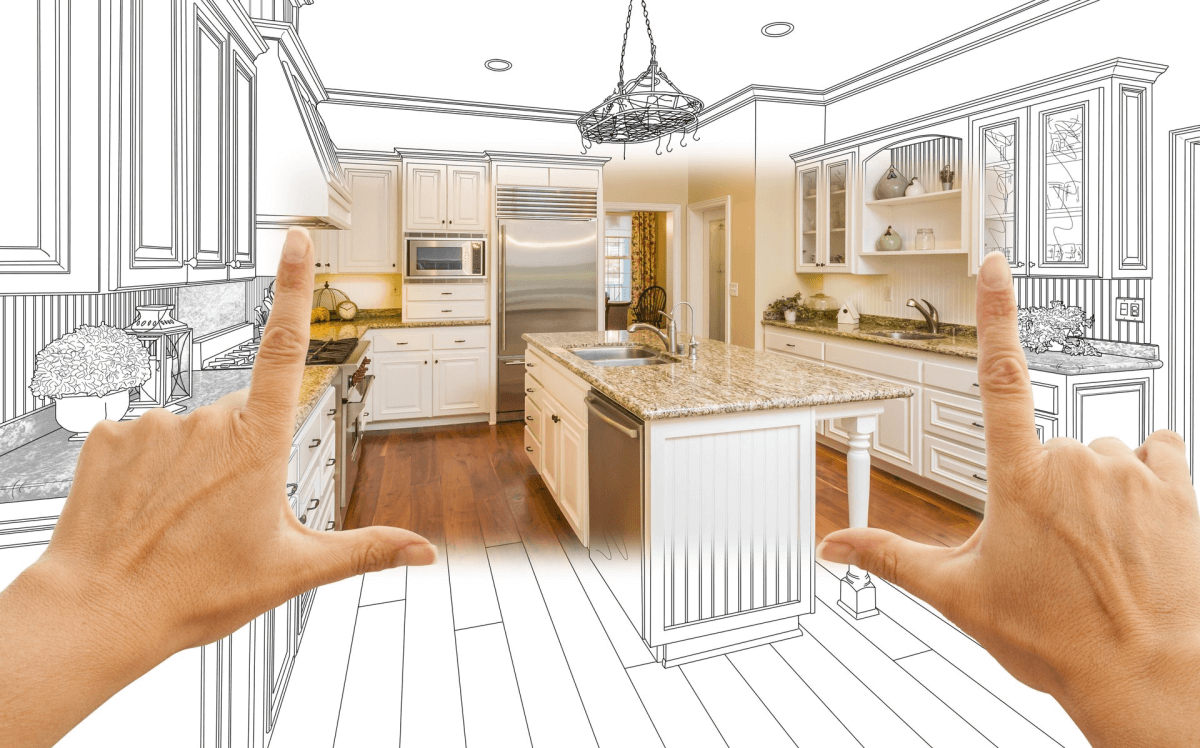

Remodeling your kitchen is one of the best mobile home remodeling ideas. It not only increases the value of your home, but also improves its functionality. You may want to install a new stove or refrigerator, upgrade your cabinets, or add a island. Kitchen islands are a popular choice for mobile homes because they provide additional counter space and storage. Additionally, they can be built at an affordable price.

A mobile home kitchen can be transformed by applying a fresh coat of paint to the walls and cabinets. It is also a good idea to replace your appliances and light fixtures. A new kitchen can transform your entire living space, making it a more comfortable place to live.

Kitchens are the heart of a home, so it is important to make sure they are well-designed. If you have an older mobile home, it can be hard to find a kitchen design that suits your taste and budget. However, with a little effort, you can transform your old mobile home into the kitchen of your dreams.

Mobile home remodeling is a great way to increase the value of your home in San Francisco and Livermore. In addition, it can help you improve your quality of life by transforming outdated rooms and installing energy-efficient upgrades. To maximize the return on your investment, you should plan your mobile home remodeling project carefully and choose a trusted local professional. Start by assessing your property and determining what areas need improvement. Then, make a list of your desired upgrades. During the planning process, make sure to include any necessary permits and a realistic timeline for completion. You should also consider the cost of any unexpected expenses that might arise during your mobile home remodeling project.

Flooring Replacement

Often, older mobile homes have floor insulation damaged by plumbing leaks or rodents. This can cause the floor to sag or feel soft. Replacing flooring is a great DIY project that can boost the curb appeal of your mobile home, as well as help to increase comfort and energy efficiency.

First, remove the existing flooring and dispose of it. Then, you’ll need to decide which material to use for your new floor. Vinyl floors are a popular choice for mobile homes, as they’re water-resistant and inexpensive. Laminate floors are also a good option for mobile homes, as they’re durable and can mimic the appearance of other materials like hardwood or stone.

Once you’ve chosen your flooring, make sure to allow it to acclimate to the temperature and humidity of your mobile home. Then, install underlayment, if desired, to add extra insulation and soundproofing. Finally, start laying your new flooring! Remember to stagger the seams and use screws instead of nails to secure them in place.

Once you’ve completed your flooring replacement, enjoy the results of your hard work! Move your furniture back in, and don’t forget to add finishing touches like area rugs or decorative throw pillows. And don’t forget to treat your newly installed floor with care, to avoid scratching or damaging it.

Bathroom Remodels

Bathrooms are one of the most frequently used areas in a mobile home. Over time, fixtures and features can begin to wear out or simply lose their appeal. When this happens, a simple remodel may be enough to refresh the space and improve its functionality. However, more extensive upgrades can also add value and appeal to the home.

The first step in a bathroom remodel is to assess the space and identify issues. This will help determine the scope of the project and determine if any permits are required.

Once the space has been analyzed, it’s time to set a budget and create a plan. This will help ensure that the remodeling projects align with your lifestyle needs and budget constraints.

In addition to maximizing space, other considerations include incorporating water-resistant materials and enhancing ventilation. It’s important to choose durable and visually appealing materials that match the existing aesthetic of your mobile home.

For example, upgrading the flooring to something more stylish and modern can make a significant impact on the overall look of your bathroom. If you’re unable to replace the entire floor, opting for moisture-resistant flooring is a great solution.

A remodeled bathroom is a key factor in increasing a mobile home’s value. An outdated or unfinished bathroom can turn potential buyers away from a property. A well-designed, fully functional and aesthetically pleasing bathroom will increase the likelihood of selling your mobile home quickly and at a desirable price point.

Add a Deck or Porch

A mobile home remodel can be a big project that can transform your living space. Whether you want to update the kitchen, bathroom, or a combination of rooms, remodeling is a great way to upgrade your mobile home and add value to your property. However, mobile homes are different from traditional site-built houses and require special considerations when planning your renovation. The first step in a successful renovation is establishing your budget and creating a plan for the work to be completed.

Many homeowners choose to focus on updating the common areas of their mobile home, such as the kitchen and bathrooms. In the kitchen, new cabinetry and countertops are popular choices, while bathroom upgrades often include new water-efficient toilets and showers. Adding a deck or porch is an ideal way to increase the amount of outdoor space in your mobile home and creates an attractive entryway to your home.

Other popular projects for mobile home remodels include painting and skirting updates. The latter can help make your home look more like a traditional house, increasing its curb appeal and perceived value. Whether you choose to hire professionals or take a DIY approach depends on your skills and comfort level with the renovation process.

A final way to boost your home’s value is by making energy-efficient upgrades. This can include replacing old appliances and HVAC systems with EnergyStar-rated options. This can help save you money in the long run and reduce your carbon footprint.

Energy-Efficient Upgrades

The best mobile home remodel projects include both aesthetic and energy-efficient upgrades. Achieving the right balance between your vision for your mobile home and practical considerations helps you avoid costly mistakes and make smart choices to boost resale value and quality of life. The most popular projects focus on kitchens, bathrooms and communal living areas. Replacing countertops and cabinetry, adding modern water-efficient appliances, repurposing room layouts to create pass-throughs between kitchen, dining and living spaces, and installing luxuries like double sinks are popular upgrades in these key spaces.

Investing in energy-efficient upgrades saves money, improves comfort and livability, and protects the environment. Sealing air leaks, insulating walls and floors, and switching out traditional incandescent lighting for LED or CFL fixtures all reduce heating and cooling costs while creating a healthier indoor living space.

For the ultimate in energy savings, upgrade to double or triple-pane windows that cut outdoor noise and condensation while reducing heat loss by up to 30 percent. This is a low-cost project with rapid results.

Installing a new roof can also be an effective way to increase energy efficiency. Replacing existing shingles or weather stripping with new, more efficient materials reduces heat transfer and improves the look of your home.

While some mobile home improvement projects require a substantial investment, financing options are available to help you get started and pay off the debt over time. Santiago Financial, Inc. specializes in mobile and manufactured home lending, offering a variety of flexible and affordable financing options to help you accomplish your remodeling goals. Contact us today to learn more about our services and apply for a loan!